- Home

- Continuous Improvement Certification Online

- Compare Pre and Post Tqm

How to Compare Pre- and Post-TQM Performance?

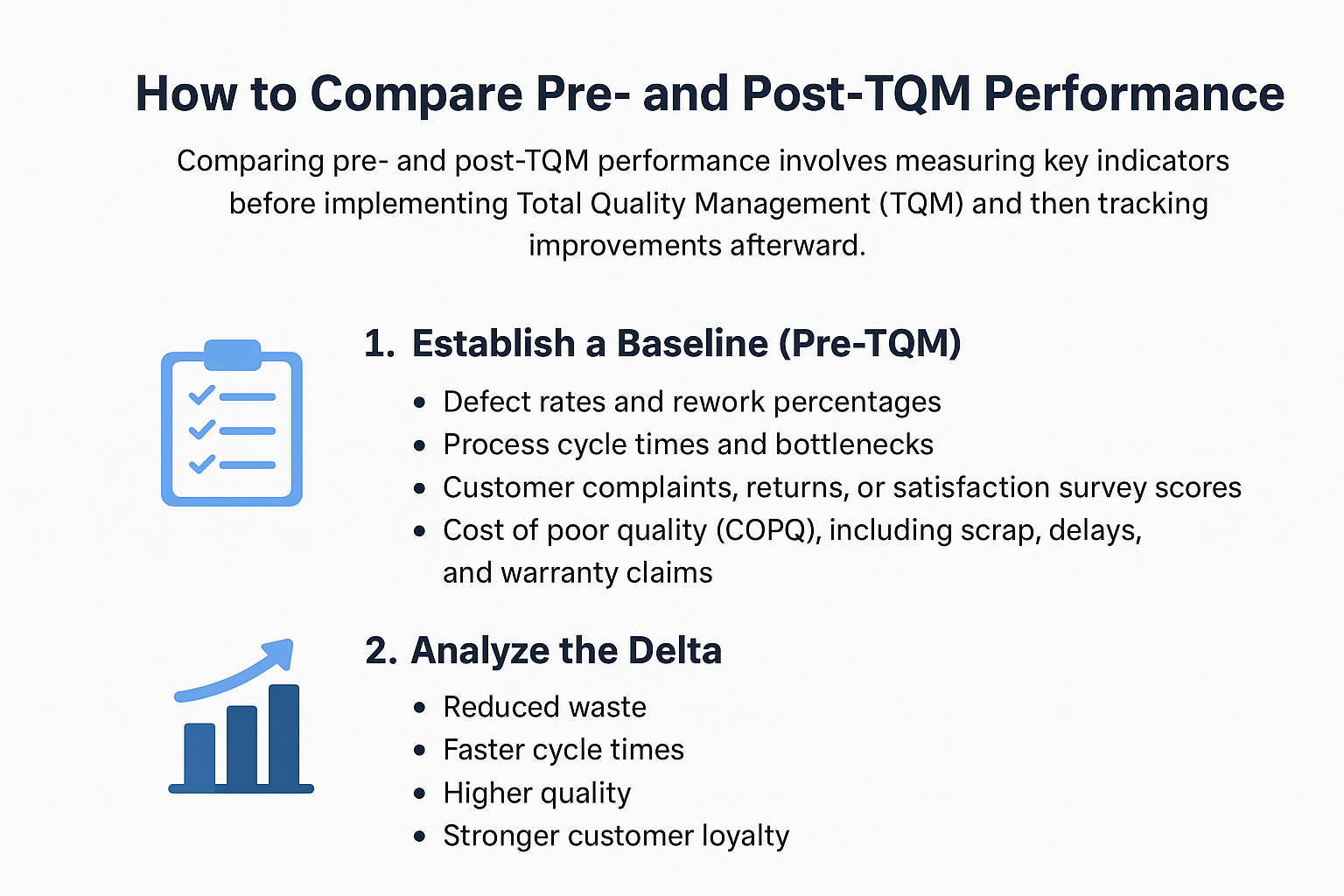

Comparing pre- and post-TQM performance involves measuring key indicators before implementing Total Quality Management (TQM) and then tracking improvements afterward. Organizations usually focus on metrics such as defect rates, process efficiency, customer satisfaction, and cost of quality. A pre-TQM evaluation establishes baseline data, highlighting inefficiencies and recurring issues. After TQM initiatives are applied, the same indicators are measured again to see the impact of new practices such as process standardization, teamwork, and continuous improvement. The real value lies in the delta between the two states: reduced waste, faster cycle times, higher quality, or stronger customer loyalty. By applying this “before and after” comparison, managers can quantify the benefits of TQM, identify areas for further refinement, and communicate clear evidence of improvement to leadership and stakeholders.

Implementing Total Quality Management (TQM) is an investment in organizational transformation. But for leaders and professionals, the central question remains: how do we know if it worked? The answer lies in systematically comparing pre- and post-TQM performance.

Step 1: Establish a Baseline (Pre-TQM)

Before any improvement initiative begins, an organization must capture baseline data. This includes current performance metrics such as:

- Defect rates and rework percentages

- Process cycle times and bottlenecks

- Customer complaints, returns, or satisfaction survey scores

- Cost of poor quality (COPQ), including scrap, delays, and warranty claims

Baseline data acts as a snapshot of “where we were” before TQM practices were introduced.

Step 2: Define Clear Objectives

Comparisons are only meaningful if goals are established upfront. A hospital might focus on reducing patient wait times, while a manufacturer might target lowering defect levels. These objectives guide which metrics are tracked both before and after implementation.

Step 3: Implement and Monitor (Post-TQM)

After TQM principles such as continuous improvement, teamwork, and process standardization are introduced, organizations should measure the same indicators captured in the baseline. For example:

- Did defect rates decrease?

- Has productivity improved?

- Are customers reporting higher satisfaction levels?

- Have costs dropped because of fewer errors?

Step 4: Analyze the Delta

The essence of comparison lies in analyzing the delta—the measurable difference between pre- and post-TQM states. Improvements in efficiency, quality, and satisfaction provide tangible evidence of TQM success.

Step 5: Communicate and Refine

Finally, results must be shared with stakeholders. Communicating improvements fosters trust and builds momentum for continuous improvement. At the same time, results often highlight new opportunities for refinement, ensuring TQM becomes a cycle, not a one-time effort.

Why It Matters?

Without a structured pre/post comparison, organizations risk claiming success without proof. By relying on real metrics, managers not only demonstrate the return on investment but also build a culture of accountability and evidence-based decision making.

- What metrics should you use to evaluate TQM success?

- How to evaluate a quality management system?

Back to T3: Evaluation of Total Quality Management

Related questions: